An aerial work platform is a piece of equipment used to facilitate access to a work area at height. It makes it possible to take one or more people, as well as equipment or tools, several meters high and thus work safely on otherwise inaccessible areas. They offer indoor or outdoor solutions to perform construction or demolition work, finishing work, maintenance, repair, upkeep, cleaning, or event operations, when permanent solutions do not exist.

Choosing the right aerial work platform

What are the different types of aerial work platforms?

There are 7 main types of aerial work platforms:

-

Low-Level Access platforms are ideal for small indoor jobs. Their compact size and light weight allow them to work on most, sensitive floor surfaces. Easy to operate and equipped with a large platform, they allow the operator to carry tools and materials, reducing the back-and-forth between the ground and the work area, making these machines a simple and safe alternative to ladders and scaffolding. The "self-propelled" models allow operators to drive at full height.

-

Push-around platforms are suitable for all indoor projects. Lightweight, these aerial work platforms operate on most sensitive floor surfaces. They are easy to transport manually or can be towed using a trailer or van. Their non-marking tires and rubber-footed stabilizers protect the floor surface. Their compact size allows them to pass through most doorways and elevators. They require little maintenance and are excellent value for the cost.

-

Vertical mast platforms are known for their maneuvering agility in tight areas. Their compact dimensions, AC motors and vertical elevation make them very easy to drive, even when elevated, in the tightest spaces, whether indoors or outdoors on flat firm surfaces. The platform extension creates an additional workspace and allows operators to reach certain areas that are difficult to access. Models equipped with a jib allow for extension over obstacles and have an exceptional tail swing of 0 inches, which makes them quite easy to maneuver. For retail, warehouse, and logistics work, the PICKING models are equipped with an electric material lifting tray.

-

The Scissor lift receives its name from the way it elevates. When rising, the crossed arms close and take the shape of scissors, allowing for exclusively vertical elevation.

These machines are divided into 2 categories:

For flat firm surfaces: Electric scissor lifts can be found on all types of stabilized ground and flooring types. They offer more compact dimensions than the diesel versions, and versions and can be used both indoors and outdoors. Most machines allow driving at full height even with full weight capacities.

Rough Terrain: With their large platform area, scissor lifts usually have a higher load capacity than all other types of platforms. Some can lift as many as 4 people to conduct the most demanding jobs. Platform extensions provide additional reach and workspace. The straight-line vertical elevation makes them quite easy to operate. Designed with rough terrain and tilt capabilities, the all-terrain scissor lifts operate on the toughest terrain. For elevation on uneven ground, stabilizers level the chassis and provide maximum stability. Some scissor lifts offer an alternative to diesel for off-road work with an electric motor, which also offers the advantage of working indoors, emission-free and silently. -

Telescopic boom lifts have an architecture that allows for straight and direct elevation (on a single axis), which makes these platforms very easy to use. Of all the machines, they have the greatest horizontal outreach and reach the highest working areas. Telescopic platforms operate on rough terrain thanks to their exceptional off-road capabilities. With proportional and simultaneous boom movements, they offer a high level of stability, precision, and safety.

-

Lightweight towed and self-propelled aerial work platforms are a very practical solution because they are towable behind a truck or van and can be easily moved from one site to another. Electrically powered, they work both indoors and outdoors, and with their stabilizers they can be used on uneven surfaces.

Choosing an aerial work platform: What are the criteria to consider?

There are four main criteria to consider when choosing a platform.

-

The working height: Depending on the height at which the task(s) are to be performed, choose the equivalent or slightly higher working height to reach the required working height. Also consider the maximum horizontal reach you may need.

-

The type of work: The different ranges of platforms correspond to the type of work to be performed. For example, an articulated platform can be used to work in hard-to-reach or tight areas, while a telescopic platform has a greater horizontal outreach than an articulated arm. An all-terrain scissor lift has a large work platform to carry more equipment, while a vertical mast lift is ideal for indoor maintenance work. The access point, doorway, and the authorized ground pressure are also important criteria in the selection of equipment.

-

The type of terrain: The type of terrain where the platform will be used is also a crucial factor to consider. On uneven terrain, it is necessary to use diesel or electric powered all-terrain platforms, on flat, firm surfaces all ranges of electric platforms can be used. Take note that some machines can only operate indoors.

-

Load capacity: This information is also a criterion to be considered. The platform must be able to support the weight of the operators plus the tools and/or materials to be loaded. In the case of materials, and to optimize space in the basket, remember to explore the options available for installation on the platform such as pipe rack, glazier kit, etc...

Knowing how to read and understand an aerial work platform range diagram

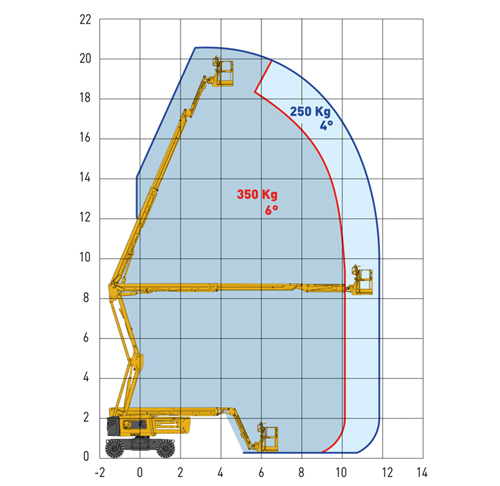

The accessible working envelope depends on each platform model and is defined by the combination of vertical elevation height and horizontal reach. This combination is represented by a range diagram, making it possible to clearly and easily identify the machine's working envelope.

Understanding the Working Envelope:

The working envelope is usually represented on a chart called the "range diagram". This is an essential graphic for aerial work platform users. This diagram is usually found in the operator's manual of the machine (which must be present in the document box attached to the platform basket).

On some aerial work platform models, the chart is printed on a plate located in the basket, allowing it to be readable at a glance in a driving or approach situation. The working envelope is a 2D representation of the aerial work platform's operating area, (usually) taking the shape of an arc. It includes a height/reach/angle diagram that makes it easy to determine the machine's access and offset capabilities. Depending on the machine, the chart can also provide essential information about the maximum weight that can be carried.

Importance of the Range Diagram:

This information is essential both when choosing the platform for the job site and when using it.

Consult the chart to choose the correct platform, for example: if an application requires a heavy weight in the basket with a maximum horizontal outreach, it is essential to check these two parameters on the chart. These two parameters can be determining factors when choosing the model and can sometimes lead to the choice of a platform whose working height is a little higher than initially thought.

Finally, when operating, the operator must be aware of the range diagram before starting work, to ensure the safety and efficiency of operations. Most machines cut off (stop elevation/extend functions) when the range diagram limits are reached. The operator will then see an indicator light on the control panel. Regardless of the machine and how it operates, it is crucial not to ignore these alerts.

Working Envelope Variations:

It is important to know that two models of aerial work platforms that look similar may have different range diagrams. This can be explained by differences in the design of the machines (materials and locations of counterweights, on-board systems, and innovations, etc.).

When consistently renting platforms from different brands, do not rely on the same expectations and always consult the range diagram. In addition, it is important to note that some machines have regular arc work curves, while others may have sawtooth shapes, requiring the arm to be retracted or repositioned to continue work when the limit of the curve is reached.

Special Working Envelope Capabilities:

Some machines offer a negative working range, which is especially useful for applications such as bridge inspections, mining, and earthmoving.

To overcome the constraints encountered on the construction site; a large displacement, work on slopes, a heavy basket load, platform manufacturers have developed innovations and options. Haulotte launched the Haulotte Extra Reach innovation in 2024, which makes it possible to increase the weight capacity of the basket, while working on sloping floors. The machine continues to elevate and work on the ground with a maximum slope of 6° (longitudinal and lateral). Some aerial work platforms have a "double load" range diagram, two working envelopes are depicted depending on the weight in the basket.

Where to Find a Range Diagram or Working Envelope:

The range diagram or working envelope are available in the machine's user manual: in the technical libraries, in the printed manual available in the platform basket, and sometimes on a printed plate (or sticker) that can be consulted directly on the machine. It is imperative to consult these charts to ensure that the use of the platform complies with the manufacturer's safety recommendations.

Checklist of Key Takeaways:

-

Working envelope representation: 2D diagram showing height, span, and angle.

-

Importance of the range diagram: Essential for choosing the right platform and for working safely.

-

Possible variations: Different shapes of working curves (regular arc, sawtooth).

-

Special Abilities: Negative work and dual load capacity.

How does an aerial work platform work?

Aerial work platforms consist of a chassis on wheels or tracks, arms, masts, or scissors, which use a hydraulic lifting function to raise and lower a platform for the purpose of transporting people. Aerial work platforms allow personnel to access tight spaces and elevated heights to perform a variety of jobs. The platform chassis supports the entire structure of the machine, while the lifting system fulfills the purpose of getting the operator to elevated work location. Work platforms are equipped with a guardrail and may also be insulated to better protect onboard personnel while working elevated.

There are several types of aerial work platforms.

.jpg)

Electric or diesel aerial work platform: When is an electric platform preferred?

Diesel aerial work platforms are mainly represented by rental companies, with an average of 70% of the fleet*. On a day-to-day basis, aerial work platform users are familiar with using diesel models. Yet, for some specific applications and construction sites, electric machines are essential and cannot be replaced by diesel models. Here are several scenarios where the electric platform will be your best ally.

*Statistics relating exclusively to the off-road articulated machine market

What are the differences between an electric/diesel/hybrid aerial work platform?

The choice between an electric, diesel or hybrid aerial work platform depends on the working environment.

Key features of each model:

-

The electric platform runs without fuel, its motor is 100% electric, and it uses batteries to operate. This makes it much quieter than internal combustion models. Another advantage is that it produces no CO2 emissions during use, making it possible to meet several environmental regulatory constraints. The main constraint of electric platforms is their battery capacity. Aerial work platforms benefit from innovation in the energy storage industry. The weight of the batteries is increasingly reduced, performance is increased, but despite these advances, battery capacity still does not equal the work capacity a full tank of diesel provides.

-

The internal combustion/diesel platform is suitable for outdoor use, equipped with a diesel or HVO (Hydrotreated Vegetable Oil or Biofuel) engine. They generally have a longer duty cycle than electric platforms. Their main disadvantage: a more polluting, noisier engine leading to more nuisance for operators and surrounding people.

-

The hybrid or dual-fuel platform is versatile and can be used both indoors and outdoors. It is an aerial work platform equipped with two energy sources: an internal combustion engine (usually diesel or petrol) and an electric system powered by batteries. This type of platform is designed to offer great versatility, allowing it to adapt to both indoor and outdoor environments. At Haulotte, the machines in the PULSEO range offer all-terrain electrical equipment equipped with a Range-Extender, a removable and interchangeable generator solution, which brings more flexibility and independence to construction sites without access to electricity.

On which construction sites should you choose an electric machine?

-

Construction sites located in LEZs: Low emission zones (LEZs) are a tool used by administrations to improve air quality. Their implementation responds to the need to protect public health, especially in large urban areas and cities. A LEZ is an area where vehicle traffic is restricted according to specific terms and conditions defined by the local government. In Europe, there are 320 LEZs*, all of which have the same objective: to protect the health of local residents living in the densest and most polluted areas. In Northern Europe, some construction sites located in LEZs already limit access by prohibiting polluting equipment. Given the international climate agreements, it can be speculated that regulations will be increasingly strict in the coming years. In construction sites located in LEZs, the use of machinery that emits polluting emissions may be prohibited. In this case, the electric or hybrid aerial work platform remains the best solution, it does not emit any polluting emissions (VOCs, NOX), their absence is also a major asset in densely populated areas. *Source: Ministry of Ecology, France - 2024

-

Night construction site in an urban center: Night work in urban centers may impose strict constraints on noise levels. In these circumstances, the construction machinery authorized to work there must have a low noise level. Each site defines the permissible noise level, considering the surrounding conditions: type and duration of the work, repetition of maneuvers, proximity to homes, density of the surrounding population, etc. Electric platforms, which are quiet by nature, make it possible to comply with these constraints while guaranteeing the safety and efficiency of operations. By limiting noise pollution, they minimize disruption to surrounding residents and workers.

-

Interior construction site with cohabitation: public places, pedestrian street, airport: Construction sites in shopping malls, pedestrian streets, or airports require equipment that produces zero emissions and generates minimal noise. Electric platforms perfectly meet both requirements, making it possible to work safely and without disrupting the activity of public places or critical infrastructure. They are ideal for environments where working near the public is unavoidable.

-

Construction site labelled "green" or prohibits internal combustion engines: Construction projects labelled "green" or those located in areas where combustion engines are prohibited (e.g., certain natural parks or protected areas) require environmentally friendly solutions. Electric platforms, with their zero emissions and quiet operation, are the equipment of choice for these job sites. They make it possible to comply with strict environmental standards while still ensuring optimal performance.

-

Indoor and Outdoor Construction site with the PULSEO range: Haulotte's PULSEO range offers electric aerial work platforms, allowing for both indoor and outdoor use. These platforms combine the advantages of electric and diesel engines, offering great flexibility of use. Operators can easily switch between charging modes, tailoring the machine to the specific constraints of the jobsite. Whether it is for indoor work requiring low noise pollution and zero emissions, or for outdoor work requiring longer duty cycles, the PULSEO range is the ideal solution.

The choice between an electric and a diesel platform depends on many factors, including environmental constraints, noise pollution, and the requirements of the jobsite. Electric platforms are particularly suitable for urban, night-time, indoor and "green" construction sites. Diesel platforms, on the other hand, remain a robust, self-contained solution for large-scale construction sites requiring extended use.

Finally, hybrid platforms, such as those in the PULSEO range, offer unparalleled versatility, combining the advantages of both technologies to adapt to a variety of situations. Haulotte's PULSEO range includes many models of aerial work platforms that incorporate a removable and interchangeable Range Extender. This built-in generator ensures fast recharging of the batteries. Installed in less than 5 minutes, it recharges the battery to 80% capacity in 3 hours. During recharging, the operator can still use the full capabilities of the machine, ideal for job sites without access to electricity.

By integrating these machines into your projects, you will not only contribute to better operational performance but also contribute to respect for the environment and the well-being of workers and residents.

How much does a cherry picker cost?

Platform prices vary depending on the size of the machine. A low-level platform can cost less than €2,500 ($2850 US) while a high-rise model can cost up to €1 million ($1,140,415 US).

How do you transport a cherry picker?

Transporting a cherry picker or boom lift can be challenging and safety is key. It is important to hire a shipping or logistics specialist.

Before transporting an aerial work platform, always refer to the model-specific Operator's Manual for transport instructions. When possible, transport the aerial work platform with its basket placed horizontally on the trailer floor. Select the best platform and trailer combinations, you must refer to the Operator's Manual to place the basket in a safe position.

There are three key steps that need to be followed when transporting an aerial work platform:

Step 1: Secure it to the truck or trailer for transit

-

Always use the turntable rotation locking pin during transport

-

Turn the key to the off position and remove it before transport

-

Scan the entire machine for loose or unsecured components

Below is an example of transportation

Step 2: Securing the platform

-

Check that the jib and basket are in the stowed position

-

Secure the basket with a nylon strap placed parallel to the strap guides. Do not use too much downwards force while securing the arm

-

Protect the basket support on the opposite side of the nylon strap with a shock-absorbing support, such as foam, gum, or wood

Step 3: Securing the chassis

-

Use chains rated for the correct load capacity

-

Use a minimum of six chains

-

Adjust the bindings to prevent damage to the chassis and paint by the chain

-

For a diagram, refer to the transportation instructions in the Operator's Manual

It should also be noted that when loading or unloading an aerial work platform (MEWP) on a public road, users and operators must ensure that all measures have been taken to protect people in or near the area. These measures are not exhaustive and may include:

-

Warning cones or signal strips

-

Signaling staff with reflective clothing

-

Personnel with flags to warn people and other vehicles of the presence of the machine

More information can be found in ISO 18893:2014 (Mobile aerial work platforms: safety principles, inspection, maintenance, and operation – Section 6.8.3 – Transportation and movement on public roads).

Haulotte has developed the Haulotte Activ'Lighting System, which optimizes visibility during loading and unloading operations at night or in low-light conditions. The system incorporates strategically placed LEDs that illuminate the ground around the machine as well as several parts of the boom: the upper and lower control boxes, the wheel lights and the rear of the counterweight. Conveniently placed around the machine, these lighting points provide better visibility to the operator and make them more visible to the environment.

Launched in 2024, the transport handle makes it possible to load and unload aerial work platforms safely. When positioning the machine on the trailer, the operator can hold securely to the machine and press the activation button with one hand using the ergonomically integrated button on the handle. The configuration allows the operator to hold with one hand and have one hand free to give arm, boom, or basket movement commands.

The craning of MEWP must also comply with strict safety rules

Who can use a cherry picker?

To use a cherry picker, there are rules to follow: the safety of people must be ensured, and personnel must be trained to operate the machine. Lifting equipment must only be operated by trained and authorized persons, in compliance with the standards approved by ANSI (In North America - American National Standards Institute) or the license issued by the IPAF (PAL card: Motorized Access License). The IPAF PAL card is the most internationally recognized training certificate. This training must be updated every five years.

In addition to training operators in how to operate the aerial work platform, it is essential to brief the teams to inform them of all the constraints, difficulties, and potential safety hazards on the site. Anticipating changing conditions such as the weather or the movement of objects, people or loads is a key to success.

For more information about the permit, you can read our full article: Platform Permit Everything You Need to Know.

What are the steps I need to take to operate an aerial work platform safely?

-

Do a thorough visual inspection of the aerial work platform before use to ensure there is no damage or leaks. Check the level of oil, gas, or the condition of the batteries, and the condition of the tires.

-

Make sure the work area is clear, and the ground is stable enough to support the weight of the equipment. Mark out the area as needed.

-

Wear a safety harness attached to a safety harness anchor provided on the work platform. Also wear any necessary personal protective equipment (helmet, goggles, etc.).

-

Enter the platform and close the entry door or drop-bar behind you.

-

Start the engine according to the procedure and check that all movements and controls are working properly.

-

Maneuver the platform using the joystick control to position it in the desired location. Avoid sudden movements.

-

Perform the work while staying inside the platform and avoiding swaying.

-

To descend again, make sure that the area is clear and that no one is under the platform.

-

Return the platform to the ground, turn off the engine, remove the ignition key and push-in all safety locks.

Is it mandatory to wear a harness in a cherry picker?

The requirement to wear a harness depends on the type of MEWP used. For aerial work platform lifts, whether static (1b) or mobile (3b), it is advisable to wear a short lanyard or energy-absorbing harness to prevent falls. For vertical lifts such as static vertical lifts (1a) and mobile vertical lifts (3a), wearing a harness is generally not mandatory unless required by local regulations. Exceptional cases, such as working above water, require a risk assessment to determine if a harness or life jacket is more appropriate. As a manufacturer, Haulotte recommends the use of a harness regardless of the type of MEWP, to ensure the complete safety of operators when operating the aerial work platform.

Yes, wearing a safety harness in an aerial work platform is generally mandatory in North America, depending on the regulations in force and the specific conditions of use. This depends on the rules established by OSHA and the recommendations of local safety authorities.

General principles:

-

Harness and anchorage point:

-

A safety harness must be worn and attached to an anchorage point in the platform, if specified by the manufacturer or if recommended by a risk analysis.

-

This helps protect operators from the risk of falling, especially in the event of tipping over or impact.

-

-

Risk Analysis:

-

A risk analysis must be conducted before any machine use. If the assessment identifies a risk of falling or tipping over, wearing a harness is essential.

-

-

INRS recommendations:

-

For scissor lifts, wearing a harness may not be necessary if collective protection (continuous guardrails) is deemed sufficient.

-

For articulated or telescoping aerial work platforms, a harness is almost always required.

-

-

Obligation of the head of the company:

-

The employer is responsible for the safety of workers and must provide the necessary personal protective equipment (PPE), including harnesses if required.

-

Sanctions:

Failure to comply with this obligation may result in administrative or criminal sanctions for the employer, in the event of an accident or site inspection. In summary, to know if wearing a harness is mandatory in your specific situation, it is crucial to:

-

Refer to the platform manufacturer's instructions.

-

Conduct a risk analysis.

-

Refer to local regulations and good professional practices.

For more detailed information, you can consult the OSHA and ANSI standards concerning safety at height.

In 2025, Haulotte launched FASTN. The patented FASTN system aims to increase operator safety by ensuring that the safety harness is securely anchored to the machine. As the first connected and universal fall prevention system, FASTN offers several advantages:

-

Maximizes harness use by creating an anchoring reflex.

-

Optimizes construction site safety through data collection and evaluation.

-

Ensures maximum compatibility and easy installation.

The main objective of FASTN is to ensure the safety of operators. Like seat belts in cars, FASTN helps operators create an anchoring reflex, significantly reducing the risk of falls, the main cause of accidents when operating a platform. FASTN also records all events during platform operation, making it easier to evaluate safety practices on job sites. The collection of this data makes it possible to implement targeted prevention campaigns and to conduct in-depth analyses of risks on site.

Can an aerial work platform be used on a slope?

Yes, an aerial work platform can be used on a slope, but under certain strict conditions to ensure the safety of operators and avoid accidents. Here are the key points to consider:

Manufacturer's instructions:

-

Each platform model has a maximum tilt limit specified by the manufacturer (often expressed in degrees or percentages).

-

his information can be found in the machine's user manual or on a data plate. If the slope exceeds this limit, it is prohibited to operate the aerial work platform as it may become unstable.

Compensation and adjustment systems:

-

Some platforms are equipped with automatic stabilization systems, such as stabilizing cylinders or tilt sensors. These devices allow the chassis to be leveled to a certain extent.

Risk Analysis:

-

Before operating an aerial work platform on a slope, a risk assessment must be conducted. It is important to consider:

-

The condition of the soil (grip, stability, risk of collapse).

-

The load transported (weight of operators and tools).

-

Weather conditions (rain, wind, slippery ground).

-

Compliance with safety rules:

-

The machine travel speed must be adjusted to prevent tipping over.

-

Do not use the machine if the slope is combined with other hazards (proximity to holes, ravine edges, etc.).

-

Never overload the platform, as this increases the risk of instability.

Built-in safety features:

-

Modern machines often have tilt sensors. If the slope is too steep, these sensors can stop machine operation to prevent tipping over.

In case of doubt :

-

If the slope seems close to the authorized limit, it is preferable to use a specific machine for rough terrain (such as all-terrain aerial platforms).

-

Consult a qualified technician or the manufacturer's service department for appropriate recommendations.

Using an aerial work platform on a slope is possible, but it must strictly adhere to the manufacturer's limits and recommendations, as well as a thorough risk analysis. Carelessness can lead to serious accidents.

Read also : How to choose a scissor lift ?

.jpg)

.jpg)